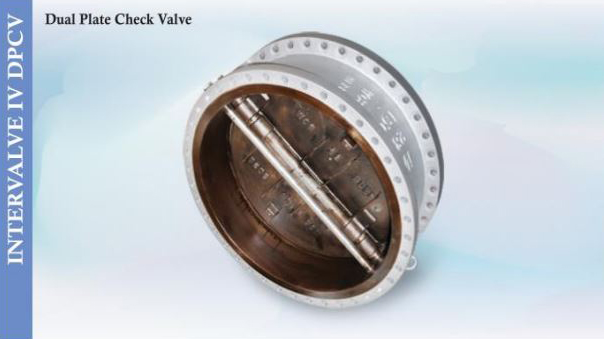

Dual Plate Check Valve

The IV DPCV is spring loaded Dual Plate check valve uniquely designed for all applications. The constructional feature rnakes the valve much smaller in size. lighter in weight & makes it more reliable in operation as compared to Conventional swing check valve.

IV DPCV valve employs dual spring loaded plates/ disc hinged on a central hinge pin- It operates on the differential pressure between fluid flow pressure & Spring torsion pressure. AS the flow pressure reduces, the plates tends to Close with a cushion effect by spring torsion force thereby restricting the reversal of fluid flow.

Silent Features :

- The product designs are in accordance to ASME B16.34 / API 594 with reliable sealing & sturdy construction to ensure excellent performance.

- The constructional feature reflects on the compactness of the valve by smaller volume, shorter length & even lighter weight.

- Suitable for horizontal & vertical pipe lines.

- These valves can be provided with soft & metal seat.

- Various end connections such as wafer / wafer lugged / double flange.

- Long life & trouble free operation.

Conformity To Codes & Standards :

| Design : | ASME B16.34 / API 594 |

| PR & Temp rating : | ASME B16.34 |

| Face to Face & End to End Dimension : | API 594 |

| Test : | Wafer Design |

| Inspection : | API 598 / EN12266 Part 1 |

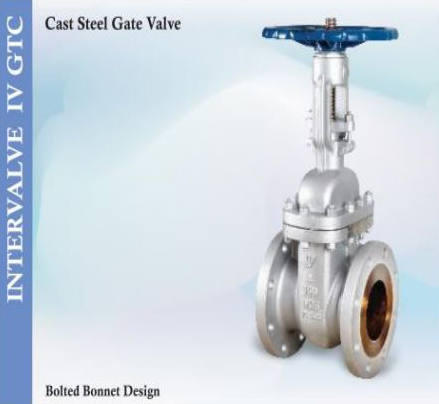

Cast Steel Gate Valve

The IV GTC range of gate valves incorporates state of the art design features to provide a rugged construction, reliable operation and long service life. The valves are suitable for normal services to most demanding applications covering all segments of the process industries such as chemical, petro chemicals, pharma, steel, alumina power plants and common utilities. Anideal valve for the flow isolation and ON / OFF duty.

Our valves can be provided with special features like water sealed gland for vacuum service, by pass arrangements for pressure balancing, special cleaning for oxygen service, multi start spindle for low effort operation, extended spindle/ bonnet for pit mounted / low temp service & NACE compliant materials for sour service in petroleum industries, etc.

The valves can be provided with motor operation wherever required. The high pressure range incorporates a pressure sealed bonnet design for reliable sealing.

Silent Features :

- The Product design are in Accordance to ANSI B16.34 / AP1600 / IBR With Reliable sealing & Sturdy construction to ensure excellent Performance.

- Outside screw & Yoke (OS & Y) Construction.

- Back seat arrangement to provide isolation of stuffing box for On-line serviceability.

- All trim material available as per API 600.

- Pressure seal bonnet for ASME #900 and above to provide excellent sealing against increased line pressure.

- Fully guided wedge to ensure proper alignment while seating.

- Full range of body / Bonnet & Trim material available.

- Valve by - pass / Deep stuffing box arrangement optionally available.

- Valves are available in flange End & Butt weld ends connections (other end connections can be provided on request)

- Gear / electrical operator can be provided, if required.

- Locking arrangement can be provided with hand wheel / Gear operator, if required.

- Position indicator / limit switches for ON-OFF indication provided on request.

Cast Steel Globe Valve

- The product designs are in accordance to ASME-B16.34/ BS1873/IBR with reliable sealing & sturdy construction to ensure excellent performance

- Outside screw & Yoke (OS & Y) Construction

- Back seat arrangement to provide isolation of stuffing box for on-line serviceability

- All trim material available as per AP1600

- Pressure seal bonnet for ASME#900 and above to provide excellent sealing against increased line pressure

- Self aligning disc is provided for proper sealing

- Full range of body / Bonnet & Trim material available

- Valve by - pass / Deep stuffing box arrangement optionally available

- Valves are available in Flange End & Butt Weld End connections (Other end connections can be provided on request)

- Gear / Electrical operator can be provided, if required.

- Locking arrangement can be provided with hand wheel / Gear operator, if required

- Position indicator / limit switches for ON-OFF indication provided on request

- Parabolic disc can be provided on request

Conformity To Codes & Standards :

| Design : | ASME B16.34 / BS1873 / IBR |

| PR & Temp rating : | ANSI B16.34 |

| Face to Face & End to End Dimension : | ASME B16.10 (Upto 18") |

| flange Ends : | ASME B16.5 |

| Butt Weld Ends : | ASME B16.25 |

| Testing : | API 598 / EN 12266 PART 1 (BS 6755 PART 1) |

Cast Steel Swing Check Valve

The IV SCV range of Swing Check Valves offers optimum solution for back flow prevention in liquid and gas lines. Our special design feature provides rugged construction, reliable operation and long service life. The valve finds application in various segments of process industries covering chemical, petrochemical, pharma, steel, alumina, power plants and common utilities.

The design offers a low pressure drop operation, which makes the valve more energy efficient. Pressure sealed bonnet design are incorporated for high pressure applications for reliable sealing. Valve can be provided with an external dashpot arrangement to provide non-slam operation, it is ideal to prevent water hammer.

Silent Features :

- The product designs are in accordance to ASME B16.34/BS1868 /IBR with reliable sealing & sturdy construction to ensure excellent performance.

- Suitable for the horizontal pipe runs "NON - SLAM" arrangement i.e. Dash pot arrangement can be provided on request.

- All trim material available as per API 600.

- Pressure sealed bonnet for ASME #900 & above to provide excellent sealing against increased line pressure.

- Full range of Body / Cover / Bonnet & Trim material available.

- Valve are available in flange end & butt weld end connections (other end connection can be provided on request)

IVGE model Butterfly valve incorporates the optimum design features to provide long trouble free service in the field. This general purpose soft seated Butterfly valve has a fully rubber lined single piece body with a centric, rubber encapsulated disc construction and is available in wafer type body pattern.

The body liner which also functions as the soft seat, comes integrally moulded bonded) version and offers 100 % bi-directional sealing against to rated pressures of PN 10. The wafer style body has universal design to fit between pipe flanges of almost all popular flange standards.

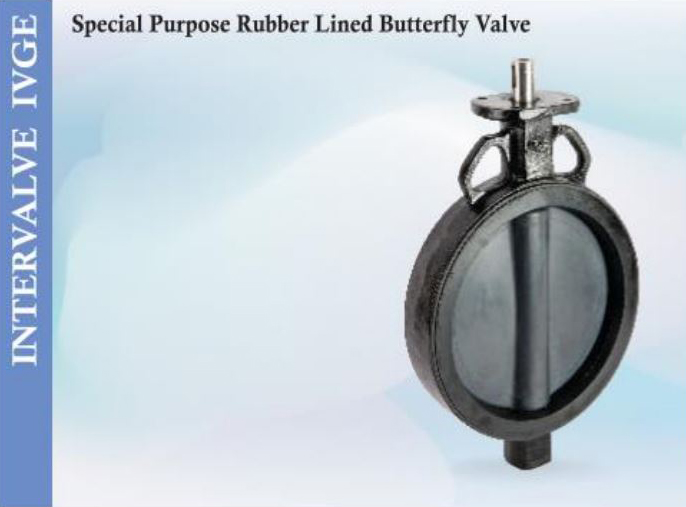

Special Purpose Rubber Lined Butterfly Valve

Technical Specification :

| Valve Type : | Centric Disc Rubber Lined Butterfly valve with a single piece body |

| Body Type : | Short Wafer |

| Seat Type : | Bounded Seat |

| End Connection : | Wafer |

| Size Range : | DN 50 to DN 350 |

| Pressure Rating : | PN 10 (max.) |

| Operating Temparature Range : | -25° to 200° C (Depending on MOC) |

| Seat Leakage | Tight Shut off |

| Operation | Handlever for size from DN 50 to DN 200 Worm gear boxes for size from DN 50 to DN 350 Pneumatic / Electric Acurator Operation - Optional |

| Standard Material Of Construction (MOC) : | SGI / WCB |

| Valve Body : | SGI / WCB (Rubber Encapsulated) |

| Valve Disk : | EPDN / Viton / Neoprene / Hypalon / Nitrile |

| Seat Liner : | SS 410 / SS 316 SH / 17.4 PH |

| Drive end & non drive end shafts : |

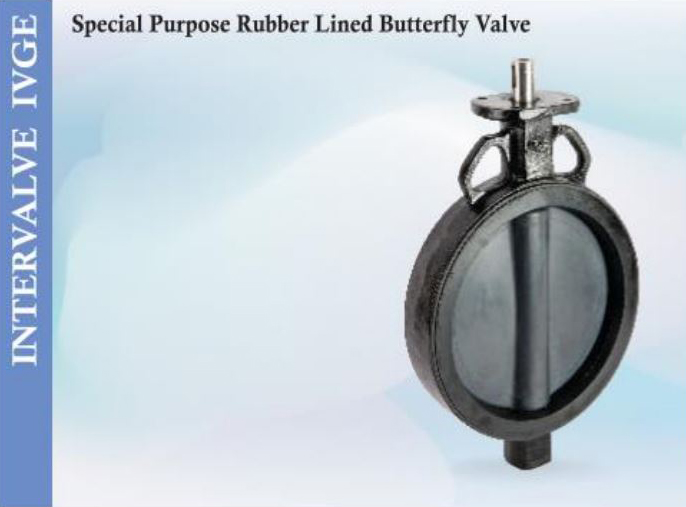

Special Purpose Rubber Lined Butterfly Valve

Technical Specification :

| Valve Type : | Centric Disc Rubber Lined Butterfly valve with a single piece body |

| Body Type : | Short Wafer (Sandwiched between flanges) |

| Seat Type : | Integrally moulded with the body |

| End Connection : | Wafer Sandwiched |

| Size Range : | DN 40 to DN 350 |

| Pressure Rating : | PN 16 (max.) |

| Operating Temparature Range : | -25°C to 80°C (Depending on MOC) |

| Seat Leakage | Tight Shut off (Bi - Directional) |

| Operation | Handlever for size from DN 40 to DN 200 |

| Standard Material Of Construction (MOC) : | CI (IS 210 FG 260) |

| Valve Body : | SGI (GGG 40) |

| Valve Disk : | Nitrile |

| Seat Liner : | SS 410 |

| Drive end & non drive end shafts : |

Floating Ball Valve, Class 150, 300, Full / Reduced Bore, 2 piece, Flanged Ends

Silent Features :

- The product design conforms to all major international standard like ISO 17292 / ASME B 16.34 / IBR with reliable sealing & sturdy construction to ensure excellent performance.

- Standardized ISO Top pad & mounting dimensions - to suit direct mounting of actuator.

- Double body & stem seal design.

- 100% interchangeability of parts.

- Quick availability of spares.

- Optimized torque & weights of valves.

- Gear / electrical / Pneumatic operator can be provided, if required.

- Valves are available in flange end & butt Weld end connections (other end connections can be provided on request).

- Locking arrangement can be provided, if required.

- Special material available on request.

Conformity to Codes & Standards :

| Design & Manufacturing Std. : | API6D/ISO 17292 / ASME B16.34 / IBR / CE |

| Pressure & Temperature Rating : | ASME B 16.34 |

| Face to Face & End to End Dimension : | ASME B 16.10 |

| Flange End : | ASME B 16.5 |

| Butt Weld End : | ASME B 16.25 |

| Testing : | EN 12266-1 (BS-6755-1) / APT 598 |

| Fire Safe : | API 607 / API 6FA |

| ISO Top Mounting : | ISO5211 |

Knife Gate Valve, Model : ZFI, Series : C - 201, C - 211

| Application : | These unidirectional valves are most suitable for pressure tight shut-off for water, sea water, mild slurry, Liquid-solid mixes and dry bulk solid applications. |

| Available Sizes : | DN 50 (2") to DN 1200 (48) |

| Pressure rating : | PN3 (45 PSI).PN6 (90 PSI) and PN10 (150 PSI) depending upon housing material, primarily for liquid applications |

| Temparature Suitability : | -20°C to 250°C |

| Seating : | Resilient seat with metallic band |

| Bonnet : | Bolt on type (Optional) |

| Flange Drilling Standard : | ASME B16.5/ASME B16.47 #150/BS-EN 1092 PN 10/PN 16 |

| Modes Of Operation : | Manual, chain wheel, pneumatic, electric actuator and Hydraulic |

Knife Gate Valve, Model : ZFI, Series : C - 202, C - 212

| Application : | These unidirectional valves are most suitable for material tight shut-off for mild slurry, liquid-solid mixes and dry bulk solid applications. |

| Available Sizes : | DN 50(2") to DN 1200 (48) |

| Pressure rating : | PN3 (45 PSI), PNG (90 PSI) and PN10 (150 PSI) depending upon housing material, primarily for liquid applications |

| Temparature Suitability : | -20°C to 1100°C |

| Seating : | Integral metal seated |

| Bonnet : | Bolt on type (Optional) |

| Flange Drilling Standard : | ASME B16.5/ASME B16.47 #150/BS-EN 1092 PN 10/PN 16 |

| Modes Of Operation: | Manual, chain wheel, pneumatic, electric actuator & Hydraulic |

Knife Gate Valve, Model : ZFI, Series : C - 203, C - 213

| Application : | These unidirectional valves are most suitable for pressure tight shut-off for water, sea water, mild slurry and liquid-solid mixes. |

| Available Sizes : | DN 1400 (56") to DN 2400196), higher sizes on request |

| Pressure rating : | PN3 (45 PSI), PN6 (90 PSI) and PN10 (150 PSI) depending upon housing material |

| Temparature Suitability : | -20"C to 250°C |

| Seating : | Resilient seat with replaceable metatring |

| Bonnet : | Bolt on type (Optional) |

| Flange Drilling Standard : | ASME B16.5/ASME B16,47 #150/BS-EN 1092 PN 10/PN 16 |

| Modes Of Operation: | Manual / chain wheel through gear, electric actuator & Hydraulic |

Knife Gate Valve, Model : ZFI, Series : C - 204, C - 214

| Application : | These unidirectional valves are most suitable for material tight shut off for mild slurry, liquid-solid mixes and for dry abrasive media. |

| Available Sizes : | DN 1400 (56") to DN 2400 (96").higher sizes on request |

| Pressure rating : | PN3 (45 PS), PN6 (90 PSI) and PN10 (150 PSI) depending upon housing material, primarily for liquid applications |

| Temparature Suitability : | -20°C to 950°C |

| Seating : | Metal seat with replaceable metal ring |

| Bonnet : | Bolt on type (Optional) |

| Flange Drilling Standard : | ASME B16.5/ASME B16.474150/BS-EN 1092 PN 10/PN 16 |

| Modes Of Operation: | Manual / chain wheel through gear, electric actuator and Hydraulic |

Knife Gate Valve, Model : ZFI, Series : C - 205, C - 215

| Application : | These bidirectional valves are most suitable for pressure tight shut-off for water, sea water, mild slurry and liquid-solid mixes. |

| Available Sizes : | DN 50 (2") to DN 2400 (96") higher sizes on request |

| Pressure rating : | PN3 (45 PSI), PNG (90 PSI) and PN10 (150 PSI) depending upon housing material |

| Temparature Suitability : | -20°C to 250°C |

| Seating : | Resilient seat with replaceable metal ring |

| Bonnet : | Bolt on type (Optional) |

| Flange Drilling Standard : | ASME B16.5/ASME B16,478150/BS-EN 1092 PN 10/PN 16 |

| Modes Of Operation: | Manual, chain wheel, pneumatic, electric actuator and Hydraulic |

Knife Gate Valve, Model : MONO, Series : C - 102, C - 112

| Application : | These are bonneted unidirectional valves suitable for pressure tight shut-off for water, sea water and liquid-solid mixes. These are partially bidirectional and are glandless thereby offering low operating torque as compared to conventional knife gate valves. |

| Available Sizes : | DN 50(2") to DN 1200 (48") |

| Pressure rating : | PN3 (45 PSI), PN6 (90 PSI) and PN10 (150 PSI) depending upon housing material |

| Temparature Suitability : | -20°C to 250°C |

| Seating : | Resilient seat with replaceable metal ring |

| Bonnet : | Provided |

| Flange Drilling Standard : | ASME B16.5/ASME B16,470150/BS-EN 1092 PN 10/PN 16 |

| Modes Of Operation: | Manual chain wheel, pneumatic, electric actuator & Hydraulic |

Slide Gate Valve, Model : ZFB, Series : C - 601, C - 611

| Application : | These unidirectional valves are suitable for pressure tight shut-off upto 3 Bar (45 PSI) for powder and granular materials. Its unique design ensures minimal material retention in valve, ability to achieve shut-off in standing columns and are leak tight to environment. |

| Available Sizes : | DN 100(4") to DN 600 (24) |

| Pressure rating : | PN3 (45 PSI) |

| Temparature Suitability : | -20°C to 250°C |

| Seating : | Resilient seat with replaceable metal ring |

| Dust Enclosure : | Provided |

| Flange Drilling Standard : | ASME B16.5/ASME B16.478150/BS-EN 1092 PN 10 |

| Modes Of Operation: | Manual, chain wheel, pneumatic, electric actuator & Hydraulic |

Slide Gate Valve, Model : ZFB, Series : C - 602, C - 612

| Application : | These unidirectional valves are suitable for pressure tight shut-off upto 5 Bar (70 PSI) for powder and granular materials from flow side only. Its unique design ensures minimal material retention in valve, ability to achieve shut off in standing columns and leak tight to environment. |

| Available Sizes : | DN 100(4") to DN 600 (24) |

| Pressure rating : | PN5 (70 PSI) |

| Temparature Suitability : | -20°C to 250°C |

| Seating : | Inflatable seal with replaceable metal ring |

| Dust Enclosure : | Provided |

| Flange Drilling Standard : | ASME B16.5/ASME B1647#150/BS-EN 1092 PN 10 |

| Modes Of Operation: | Pneumatic |

Swing Gate Valve, Model : KU - STD, Series : C - 301, C - 311

| Application : | These unidirectional valves are suitable for pressure tight shut off upto 3 Bar (45 PSI) for powders and granular materials. Its unique design offers fast shut-off (less than 3 Secs, even manually) and allow shut-off in standing columns and are leaktight to environment. |

| Available Sizes : | DN 100 (4") - DN 400 (16) |

| Pressure rating : | PN3 (45 PSI) |

| Temparature Suitability : | -20°C to 250°C |

| Seating : | Resilient seated with viper seal |

| Flange Drilling Standard : | ASME B16.5/ASME B16.47#150/BS-EN 1092 PN 10 |

| Modes Of Operation: | Manual, pneumatic |